The increasing number of internet users around the world is expected to fuel the global EMI Filter Kits market. The number of internet users per 100 people increased by almost three times to 86.6 in developed regions, according to the International Telecommunication Union (ITU). Furthermore, the research and development activities related to data transmission devices and networks are also expected to propel market growth. However, it is not clear how much these factors will influence market growth.

EMI Filters are used to Mitigate or Attenuate Unwanted

Electromagnetic Noise

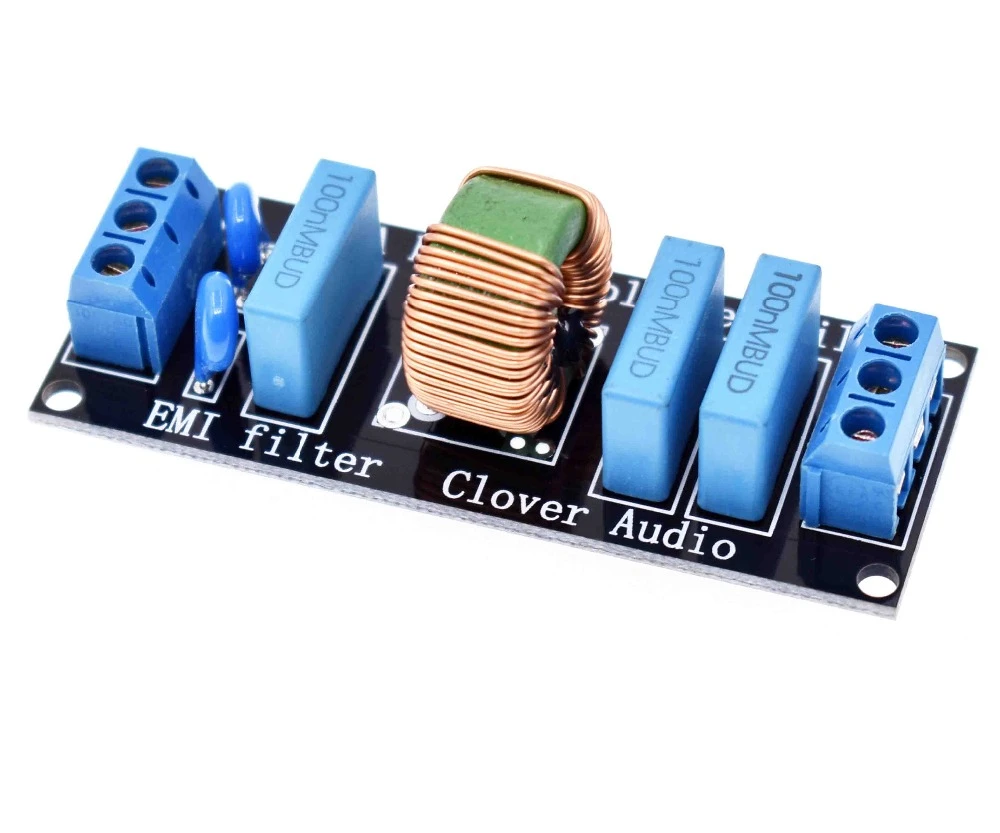

EMI filters are specialized electrical devices used to reduce the effects of electromagnetic noise. They typically have several parameters to meet the specifications of a particular application. The main parameters of EMI filters include rated voltage, rated current, leakage current, and withstand voltage. A common-mode filter will attenuate signals that are higher than ten kHz while allowing lower-frequency signals to pass without any attenuation. A single-phase filter will be most effective for applications requiring power lines in the DC direction, such as office equipment. Single-phase filters are also available for use in test and measurement equipment.

EMI can affect electronics, from personal computers to wireless routers. Filters are a great way to reduce EMI, as they reduce the effects of a specific frequency. By reducing unwanted signals, EMI filters can help ensure that electronic equipment operates at its maximum efficiency. However, filters do not eliminate all sources of EMI. Shielding, grounding, and isolation techniques may help to limit their negative effects, but these methods are not always feasible.

They Block High-Frequency Components

EMI Filter Kits are a must for RF/wireless device manufacturers who need to meet regulatory requirements for immunity and fast transient emissions. The filters help electronics meet these requirements and are often used in military and aerospace systems. They are also used in computers, factory automation equipment, patient devices, exercise equipment, and automotive battery chargers. Noise regulations have strict guidelines for the maximum noise levels that devices can produce.

High-frequency electrical noise can harm electronic devices and disrupt their functions. When it affects the functioning of electronic devices, it can result in over or under-powering. It can also damage electronic components, such as hearing aids, pacemakers, and life support sensors. EMI filter kits can prevent damage from affecting electronic devices. EMI filter kits prevent these damages by blocking electromagnetic interference. By reducing EMI, it is possible to protect your electronic devices from costly repairs.

They can Handle Short-Term Voltage Spikes

EMI filter kits can handle short-term voltage fluctuations, such as those associated with lightning strikes. These filters are characterized by the presence of amorphous cores, which reduce impulsive noise, while ferrite cores are designed to clamp voltage spikes. They also exhibit a significant reduction in attenuation over time. Amorphous cores are made of thin ferromagnetic strips wound into a doughnut shape.

Electrical noise can cause unexpected voltage spikes or ripples when it encounters sensitive analog signals. This can affect microprocessor-based components, PLCs, and processors, which are susceptible to data errors caused by voltage spikes and ripples. EMC testing is often the final step of the product development process. It is therefore important to invest in proper protection for the equipment against voltage spikes.

They may not provide an Insertion Loss Graph

You need to know how to calculate the insertion loss of a given EMI filter to choose the right one. Although the datasheet of an EMI filter usually shows an insertion loss graph, you may not find one provided by your manufacturer. Some manufacturers only give you a frequency insertion loss chart that gives you only a few specific data points, which will have little impact on your selection.

EMI filters contain two-pole LC common and differential mode sections. The corner frequencies are 50 kHz differential mode and 159 kHz common mode. Both modes shift slightly in a 50-ohm system because of the loading effects between the source and the load. You can test the filter by connecting the signal source across the input terminals and evaluating the amplitude across the output terminals. The differential mode insertion loss is also measured separately.

They may not Meet all the Application Criteria

EMI Filter Kits may not meet all the requirements for your application. The filter must meet specific circuit AC or DC voltage conditions. These two voltage ratings are not the same, and the filter’s DC rating may not reflect its performance under high AC voltage. AC-rated filters have lower capacitance values to prevent damage from reactive current heating. They may also undergo pulsed voltage testing. Depending on the level of EMI and other noise, you may have to modify the filter’s rated voltage.

To find the best EMI filter for your system, you need to carefully read the filter’s datasheet. The datasheet will display the filter’s insertion loss, which is the ratio of signal power lost between the input and the output. This figure is measured in decibels. In addition, EMI filter datasheets will show the attenuation of signals across different frequencies and ohms. The insertion loss charts will tell you how much attenuation the filter can provide if the input and output impedances are 50 ohms.

Comments